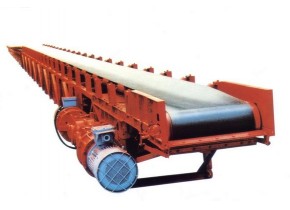

DS Belt Conveyor

Introduction

DS Belt Conveyor is used to connect different machines to make a continuous processes, it is specially designed for conveying big tire cuts. The machine mainly consists of motor, speed reducer, conveying belt, roller, machine frame and blocking plate, etc.

Structure and Principle

According to conveying materials and connecting machines, different motor power, belt type, conveying speed and blocking plate type for the conveyor are used.

Adjustable upper and lower rollers, the rollers have self-aligning core to avoid slipping or deviation during transportation.

Direct turbine worm wheel driving, can convey in horizontal or sideling directions.

PLC control system for even and accurate conveying quality ensure the whole line's stability, safety and efficiency.

Technical Data

|

Model

|

500

|

650

|

900

|

1300

|

|

Capacity(kg/h)

|

200-2000

|

|

Conveying distance(m)

|

5-8

|

|

Conveying height(m)

|

2-4

|

|

Conveying width(mm)

|

500-1300

|

|

Conveying speed(m/minute)

|

2-20

|

|

Motor power(kw)

|

1.5-3

|

|

Weight(T)

|

0.5-1.2

|