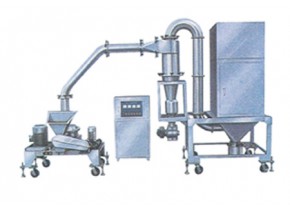

WFJ Series Mini Pulverizer

Main Application

The machine is composed of main motorauxiliary motor and electricalcontrol cabinet with the apabilities

of winnowing, nonsieve or meshcompact design and reasonable structure. Due to the negative pressure sends heat out continuously in operation,the machine is also applied for the grinding of heat sensitive materials,The pulverizer is widely applied in industries such as chemical foodstuff,pharmacy, cosmetic, tincture resin andso on,ranking world advanced levels.

Working Method

Raw material is delivered to the grinding chamber via hopper by spiralfeeder, and is cut and sheared by

the high speed cutters,then the materialis moved into the whirlwind separator and sack dust catcher by the negative pressure sucking method. The dust is collected and recycled via cloth bag or filter of dust absorption box. There is no dust flying during production so as to improve the utilization and decrease the production cost.

Technical Data

|

Model

|

15

|

20

|

|

Capacity(kg/h)

|

30-200

|

50-300

|

|

Size of input granules(mm)

|

<10

|

<12

|

|

Size of output granules(Mesh)

|

80-320(adjustable)

|

80-320(adjustable)

|

|

General power(kw)

|

13.5

|

22

|

|

Main running speed (r/min)

|

6000

|

4800

|

|

Weight(kg)

|

1200

|

1600

|

|

Overall size ( L×W×H)(mm)

|

4200×1200×2700

|

4700×1250×2900

|

|

Model

|

30

|

60

|

80

|

110

|

|

Capacity(kg/h)

|

30-800

|

50-1200

|

100-2000

|

200-3000

|

|

Size of input granules(mm)

|

≤ 10

|

≤ 10

|

≤ 15

|

≤ 20

|

|

Size of output granules

(Mesh)

|

60-450 (adjustable)

|

60-450 (adjustable)

|

60-450 (adjustable)

|

60-450(adjustable)

|

|

General power(kw)

|

46

|

84.15

|

145

|

230

|

|

Main running speed(r/min)

|

3800

|

2800

|

2200

|

1480

|

|

Weight(kg)

|

2800

|

4500

|

9500

|

16000

|

|

Overall size ( L×W×H)(mm)

|

6640×1300×3960

|

7500×2300×4530

|

9800x2600 x6800

|

13000x3500 x7200

|